3D PRINTING TECHNICAL PARTS AND SPECIALTY MATERIALS WITH SLS (SELECTIVE LASER SINTERING)

Additive Manufacturing in SLS is one of the most reliable methods to produce functional parts and accurate prototypes. rpm purchased two SLS machines and founded the business in 1997. Since then, SLS has continued to be a core production technology for rpm.

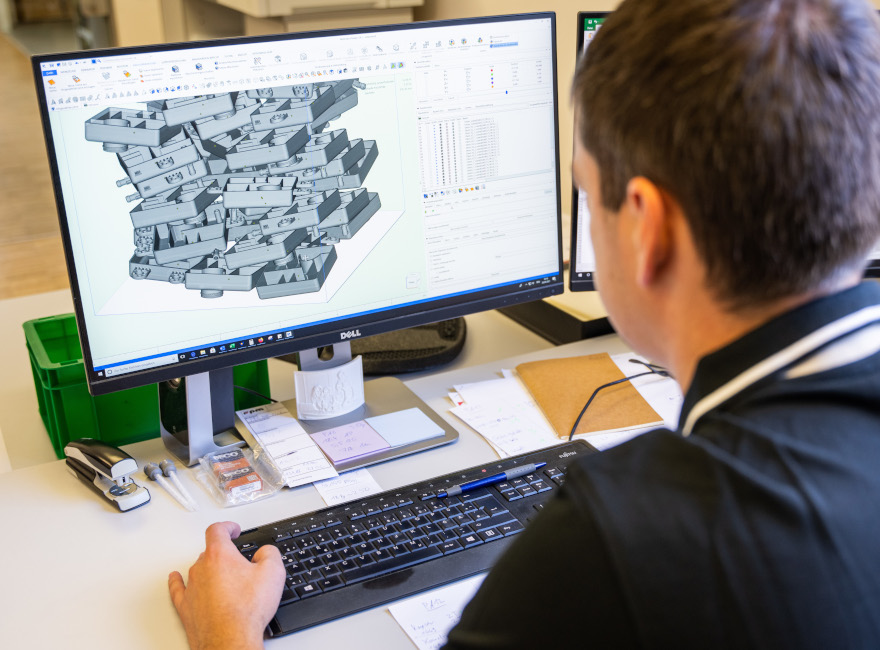

In 2020, rpm invested in the newest technology from the machine manufacturer Farsoon to produce with advanced and special materials. The machines also match current industry standards in part accuracy, speed and reliability. From automotive spare parts to automation systems to consumer goods to industrial applications, series production is an increasing percentage of SLS output at rpm.

rpm has a particular focus on additive manufacturing of technical parts, large fused parts and items that require special quality assurance or assembly. As an ISO 9001:2015 certified facility, we have high standards for documenting and measuring each part that leaves rpm.

Over the past two years in particular, rpm has mastered production with challenging materials like PA6, PA6 MF, large polypropylene (PP) parts and product-ready elastic TPU in fine-detail lattices. Particularly when projects require a certain technical accuracy, tight tolerances or post-processing such as milling or joining, rpm is a strong partner with all the necessary services in-house.

Years of Experience

Parts Produced

Performant Materials

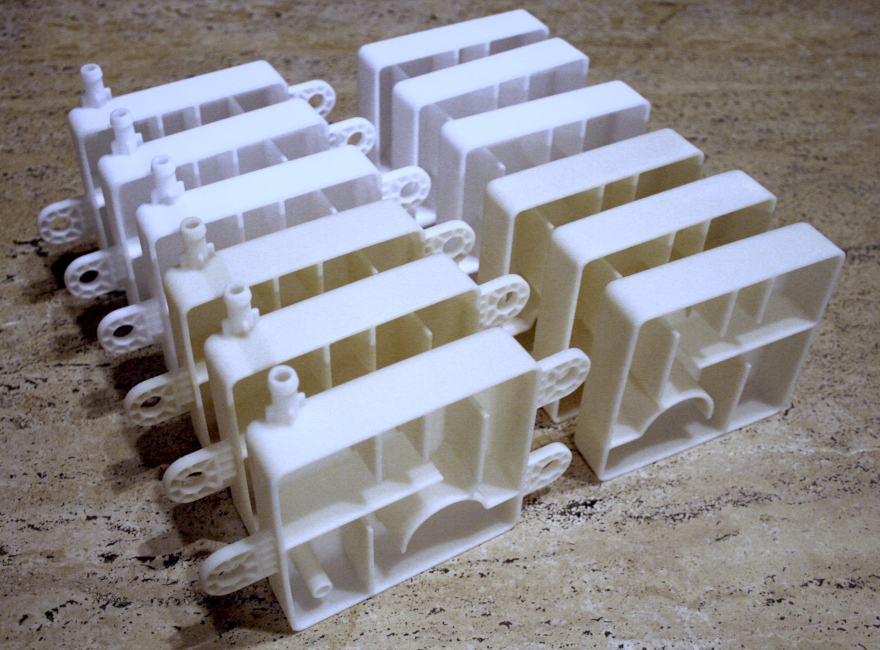

SLS ADDITIVE MANUFACTURING IN SMALL SERIES

From 20 to 2,000 parts SLS can be an attractive alternative to traditional plastic casting. Particularly interesting use cases are for complex geometries or to achieve fast turn-around times while waiting for series tooling. Increasingly, SLS parts with finishing are being used to cover the entire pre-series phase to support continual product development without locking in a final hard tooling. Other very interesting business cases are holders for sensors and customized industrial machine components that are only ever needed in the range of 50 – 500 parts.

TECHNICAL ACCURACY AND VALIDATION OF FUNCTIONAL PROTOTYPES

The initial core competency of rpm was producing technical and functional prototypes for use in testing environments. Our ISO 9001:2015 and TISAX certifications reflect our diligence in ensuring a high part quality and data security along the product development cycle. rpm provides the option for part validation with digital scanning or other testing systems. Our customers tend to trust us over decades to develop next-generation products together.

3D PRINTING LATTICE IN PA12 and TPU

With decades of experience in SLS and a particular focus on lattices for Digital Light Synthesis (DLS), rpm counts themselves among the leaders in functional lattices for end-use parts. Driven by customer demand, we have made particular advances in performance lattices in TPU. Increasingly we are seeing real-world applications for padding elements, automation tools and customized dampening elements. But futuristic, lightweight parts for electric vehicles and UAVs also find their way to the rpm production floor.

SERIES PRICING FOR SLS PARTS

Supported by high-output Farsoon SLS printers, rpm has a dedicated pricing for series production that often matches or beats other comparable Laser Bed Fusion technologies. Series parts make up an increasing percentage of additive manufacturing output at rpm. Parts which were previously produced in vacuum casting are now moving to be made in SLS.

PAINTING AND DYEING FOR END-USE 3D PRINTED PARTS

Advances in post-processing have made 3D printed parts from SLS ready for end-use products. One of the main additional services is adding a unique color signature. Depending on the application, surface smoothing and dying of parts can provide a clean matte finish. Or parts can be sealed and painted to provide additional protection to the part in use and receive a grade of finish up to auto-exterior quality when required.

VAPOR-FUSING TO SEAL PARTS AND IMPROVE MECHANICAL PROPERTIES

Having a sealed exterior surface for powder-based parts brings significant advantage to the mechanical properties. This process creates a smooth exterior surface similar to a moulded plastic part. That seals against moisture and chemicals, improves cleaning for medical applications and removes surface roughness for applications in automation and industrial goods. This also works with TPUs, opening up a new range of applications for flexible, end-use products even for use in harsher environments.

INFILTRATION TO SEAL PARTS

For functional parts in automotive and industrial goods, using infiltration as post-processing results in watertight and airtight parts. With our internal testing systems, all parts can be verified with various media before leaving the facility. Infiltration can also be an important step prior to painting to achieve optimal finishes.

JOINING LARGE SLS PARTS WITH TECHNICAL FINISHING

At rpm, we also work in large format. The same post-processing stations we established for RIM (Reaction Injection Moulding) parts also handle our SLS parts. Our Farsoon machines already produce large parts at 37 x 37 x 42 cm, but we often fuse multiple parts together to build casings and covers for applications like utility vehicles. Our expertise in other technologies like RIM gives us a particular advantage to produce these large parts with in-house tools.